The Main Principles Of Santa Clarita Powder Coating

Wiki Article

The Buzz on Powder Coating Santa Clarita

Table of ContentsThe 10-Second Trick For Santa Clarita Powder CoatingRumored Buzz on Santa Clarita Powder CoatingTop Guidelines Of Powder Coat Santa ClaritaThe Buzz on Powder Coating Santa ClaritaFacts About Powder Coating Santa Clarita RevealedThe 20-Second Trick For Powder Coating Santa ClaritaUnknown Facts About Powder Coating In Santa ClaritaThe smart Trick of Santa Clarita Powder Coating That Nobody is Discussing

This procedure puts a layer on a thing electrostatically, which is then cured by warm. The coating is harder and tougher than traditional paint. The procedure is helpful for coatings on steel used in lots of house home appliances, light weight aluminum items and also automobile parts. Residence of powder covering [modify] Powder covered bicycle structures and parts, Since powder coating does not have a liquid provider, it can create thicker coatings than standard liquid coverings without running or drooping, and also powder layer generates minimal appearance distinctions in between flat coated surface areas and also up and down coated surface areas., this may limit the capacity to reuse the overspray. (VOC) right into the environment.

How Powder Coating In Santa Clarita can Save You Time, Stress, and Money.

View Powder Coating Plus, Inc. Santa Clarita in a full screen map

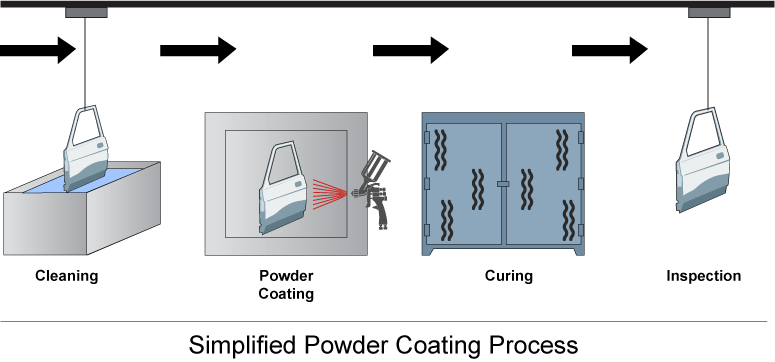

UV-cured powder will certainly melt in 60 to 120 secs when getting to a temperature 110 C and 130 C. When the dissolved layer is in this temperature level window it is immediately cured when exposed to UV light. The powder layer process includes 3 standard steps: part prep work or the pre-treatment, the powder application, and also treating.

is essential before the powder finishing procedure. It can be done by a variety of chemical and also mechanical methods. The option of the method relies on the size and also the material of the part to be powder layered, the sort of pollutants to be removed as well as the efficiency demand of the completed item.

What Does Santa Clarita Powder Coating Do?

Cast steel shot or steel grit is used to tidy as well as prepare the surface prior to coating. This approach of preparation is very efficient on steel parts such as I-beams, angles, pipelines, tubes as well as large made pieces.The kind of nozzle made use of will certainly depend on the form of the work surface to be painted and the uniformity of the paint. The item is after that warmed, and the powder melts right into a consistent film, and is after that cooled to develop a difficult coating. It is likewise usual to warm the steel first as well as after that spray the powder onto the hot substrate - santa clarita powder coating shop.

The Of Santa Clarita Powder Coating

In this case, the powder picks up a favorable charge while rubbing along the wall surface of a Teflon tube inside the barrel of the gun. These charged powder bits after that adhere to the grounded substrate.Additional heating is generally called for to end up healing the layer. This technique is typically utilized when the wanted density of layer is to exceed 300 micrometres. This is how most dishwasher shelfs are layered. Electrostatic fluidized bed covering [edit] Electrostatic fluidized bed application utilizes the exact same fluidizing strategy as the standard fluidized bed dip process however with a lot more powder depth in the bed.

Not known Factual Statements About Powder Coat Santa Clarita

Charged fragments of powder step upwards and also form a cloud of billed powder over the fluid bed. When a based part is travelled through the billed cloud the particles will certainly be attracted to its surface. The components are not preheated as they are for the conventional fluidized bed dip procedure.

Some Known Incorrect Statements About Powder Coat Santa Clarita

HAA polyesters often tend to overbake yellow more so than TGIC polyesters. The treating timetable could differ according to the supplier's specs. The last demonstrates significant decrease of treating time.To paint or to powder layer? Why pick powder finish finishes over paint? Powder finishing, pop over to this site on the various other hand, is an extra innovative method.

The Ultimate Guide To Santa Clarita Powder Coating Shop

Powder finish is used as completely dry powder via an electrostatic process, after that cured with warm. It is popular for offering top quality surfaces in terms of both capability and also general appearance. The powder layer finishes are not just sturdy however flexible as well. It can be used on various surface areas, consisting of steel, concrete, steel, as well as plastic.There are 2 kinds of powder finish, thermosets and thermoplastics. powder coating in santa clarita. Polycarbonate powder sites layer finishes end up being liquid as well as very soft when heated up. This removes chemical bonding. This procedure makes the powder finishing both relatively easy to fix and also multiple-use. Thermoplastic finishings often tend to be thicker, as well as go to these guys therefore a lot more sturdy contrasted to thermoset finishes. For this factor, they can be utilized for a wide variety of points from metal, automobile parts, and also even fridges.

Some Known Details About Santa Clarita Powder Coating Shop

Prep work is the very first action of the process as well as perhaps the most important one. This step figures out exactly how well the powder coating adheres to the metal surface area, and there are various alternatives for cleansing as well as prepping the surface.Report this wiki page